The analysis of metal sculptures correspond to an understanding of the technology used by the artist. To do this, one can determine the manufacturing process (lost wax casting, sand casting, molding …) and the alloy used.

The manufacturing process is determined by optical observations or through imaging (X-rays, CT- Scan… ).The characterization of the alloy is generally done by analytical means.

In addition to determining the general family of the alloy (bronze, brass, steel, stainless steel, aluminum alloy, etc.), a more accurate determination (quantitative) of the various components of the alloy can help to confirm or disprove the attribution to a certain artist or smelter. The quantification of trace elements (< 0.5 wt%) can also help to correlate the work at a given period.

Finally, on archaeological objects, the analysis of the corrosion layer as well as its profile will help to confirm the authenticity of the corrosion as a natural phenomenon versus artificial “patinations” implemented by counterfeiters.

• Works analyzed

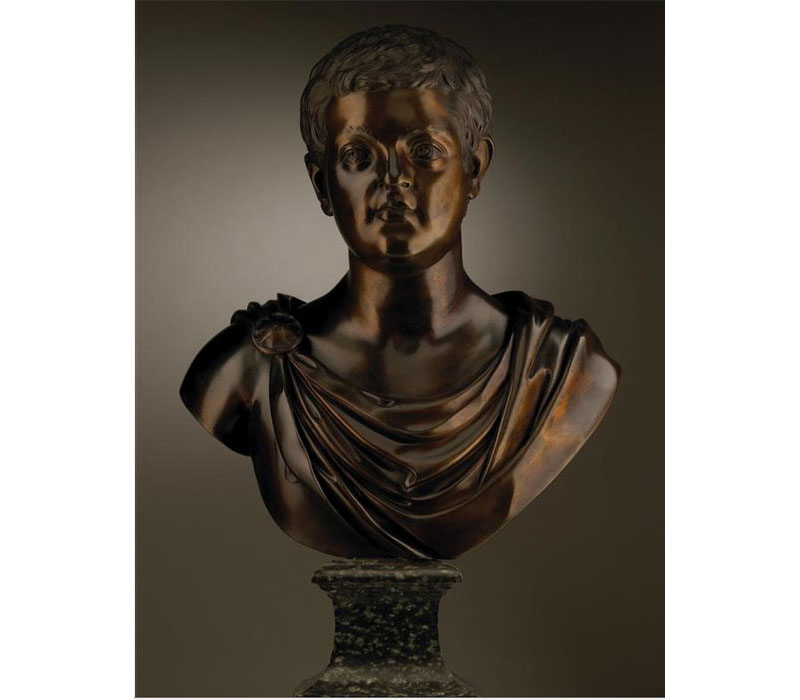

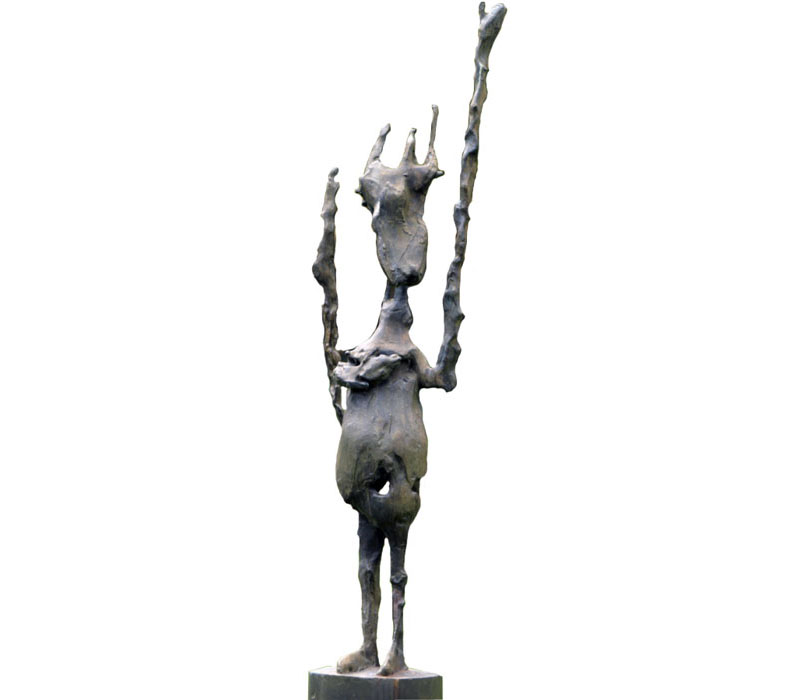

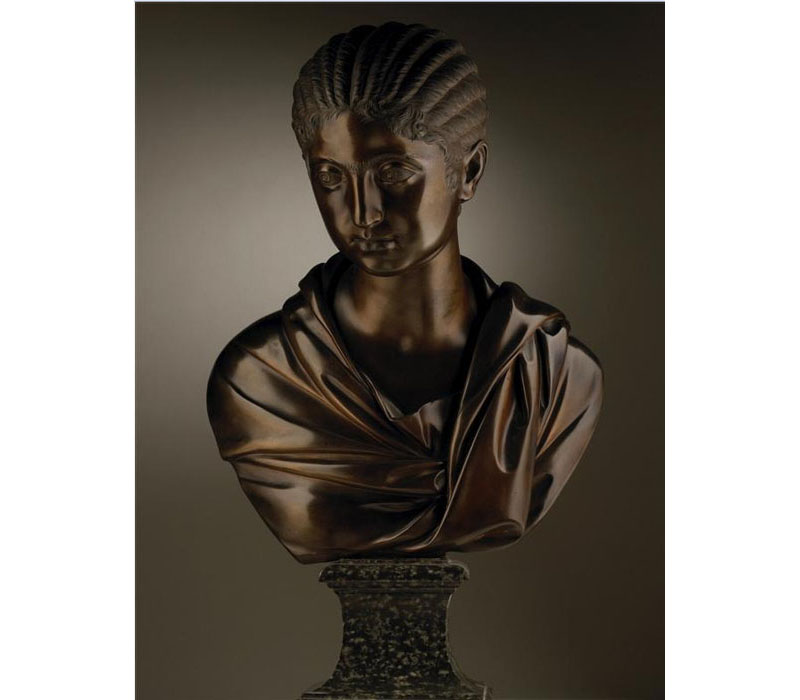

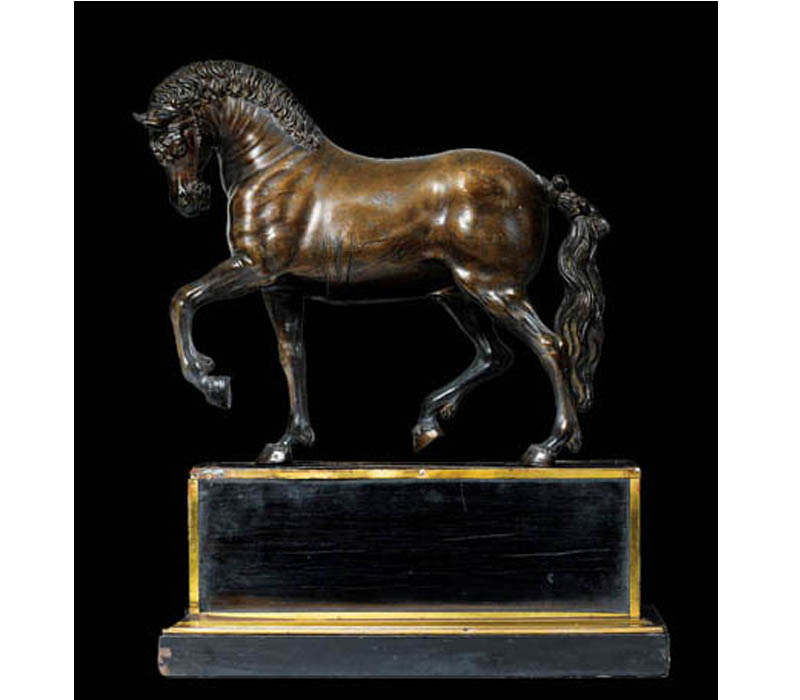

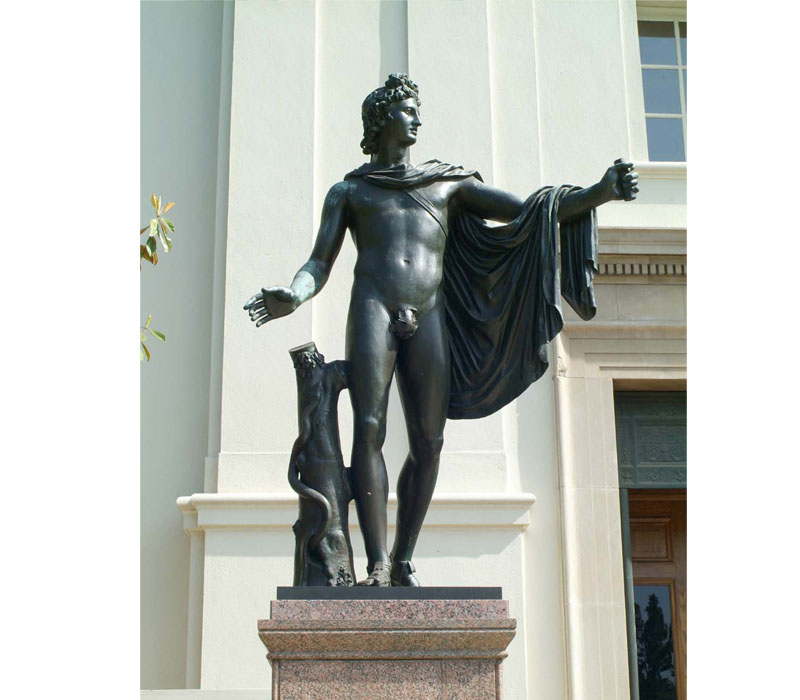

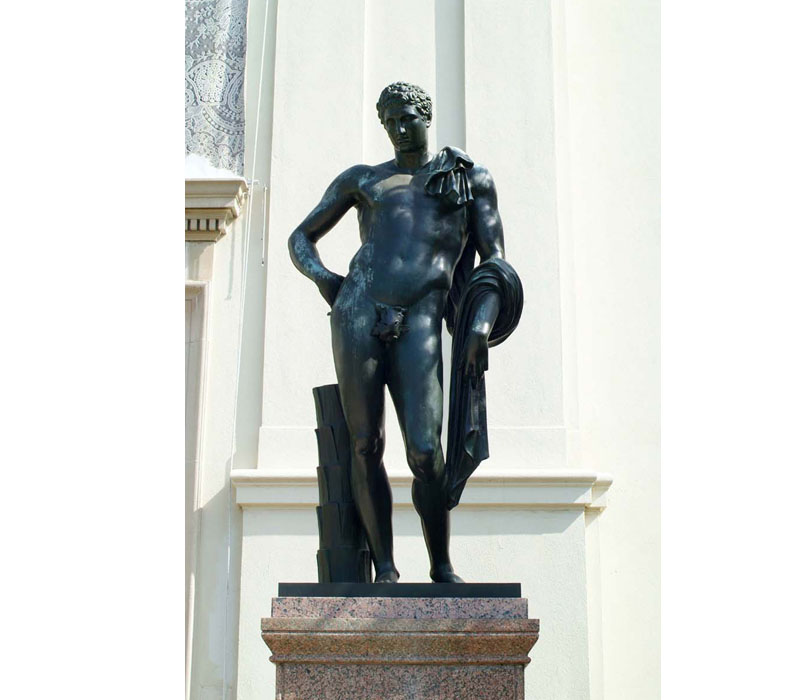

Archaelogical artefacts from the IId millenium B.C to the XVIth c. A.D., Biller the Elder, Pilon, Girardon Jacquiot, Anguier, Le Sueur, Bernini, Cipriani, Brancusi, Stanley, Adams, Frink, Hepworth, Maillol, Magritte, Calder, Miro, St Phalle, etc.

• Example of current project

Les bronzes de la Renaissance au XIXème s. (2009 -act ).

• Publications

1) Conserving Outdoor Sculptures, The Stark Collection at the Getty Center, 288 pp. Getty Center pub., 2010.

2) in “Bronzes Français : matériaux et techniques de la sculpture en Bronze du 16e au 18 e siècle, Archetype Pub., Londres, à venir (fin 2013)”